Power to

compete

From Pavement Circle Track to Drag to Off-Road Racing, from Rally Racing to Autocross, and Dirt Circle Track and Road Racing/Touring, Hawk Performance gives you the braking power to compete on all courses. We are the Official Brake Product for motorsports organizations like the National Auto Sport Association (NASA), Sports Car Club of America (SCCA), Porsche Club of America (PCA) and Stadium Super Trucks, along with numerous performance and racing driving schools. Hawk Performance® gives you the confidence to go into corners faster and help you find those fractions of seconds to bring home the trophy.

*Motorsport pads do not include shims.

compare

our compounds

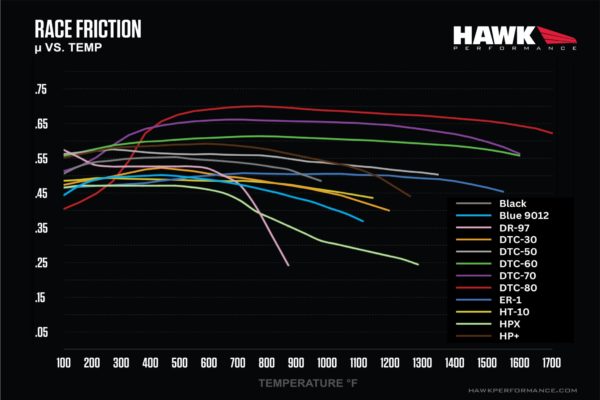

Check out the pad material's friction level against the brake rotor surface as brake system temperature increases. The higher the Mu level, the more stopping power will be achieved for a given amount of brake pedal pressure.

Compare Compounds